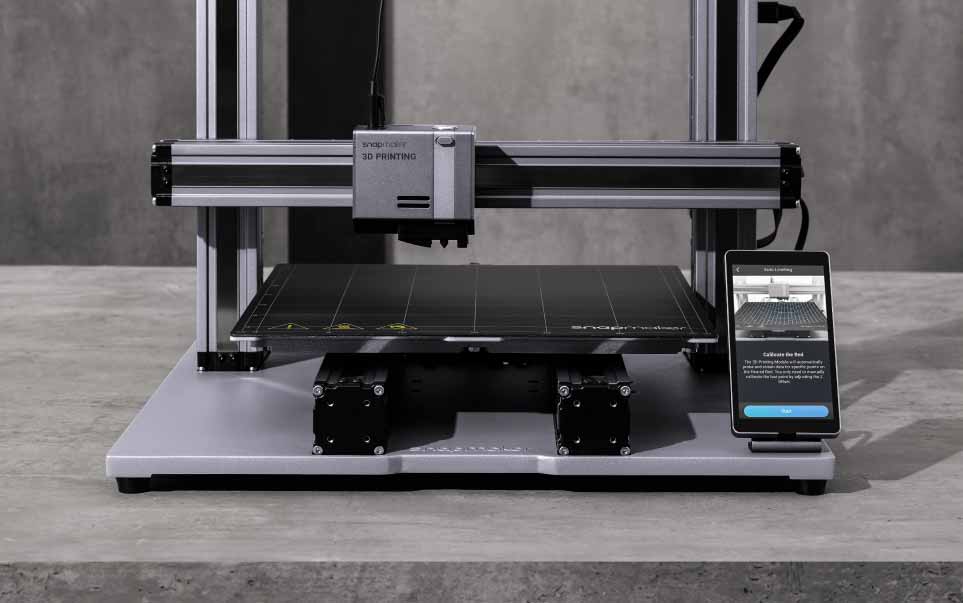

Achieving consistent 3D printer filament flow is essential for high-quality 3D prints, especially in small-scale prototyping where precision is critical. However, issues like filament jams, under-extrusion, and over-extrusion can disrupt prints, leading to failed prototypes or wasted material. This guide provides practical steps to diagnose and resolve common filament flow issues on single-extruder 3D printers, focusing on maintenance, settings adjustments, and troubleshooting techniques to ensure smooth, reliable prints.

Understanding Filament Flow Issues

Filament flow problems occur when the filament doesn’t extrude consistently through the nozzle. Common symptoms include gaps in prints (under-extrusion), excessive material filament (over-extrusion), or complete print failure (jams). These issues can stem from improper printer settings, filament quality, or mechanical problems. By systematically addressing these factors, you can achieve consistent extrusion for detailed prototypes.

Issue 1: Filament Jams

Symptoms

The filament stops extruding entirely, or the extruder motor skips steps, producing a clicking sound. Prints may fail mid-process, with no filament coming out of the nozzle.

Causes

- Clogged Nozzle: Debris, dust, or degraded filament can block the nozzle.

- Improper Filament Path: Filament may bind or tangle in the extruder or spool.

- Incorrect Temperature: If the nozzle is too cool, the filament may not melt properly.

- Worn Extruder Components: A damaged extruder gear or PTFE tube (in Bowden setups) can impede flow.

Solutions

- Clean the Nozzle: Heat the nozzle to the filament’s printing temperature (e.g., 200–220°C for PLA). Use a cleaning filament or perform a cold pull: insert filament, heat it slightly below printing temperature, let it cool, then pull it out to remove debris. For stubborn clogs, use a 0.4 mm acupuncture needle or drill bit to clear the nozzle manually.

- Check the Filament Path: Ensure the filament feeds smoothly from the spool to the extruder. Untangle any knots and confirm the spool holder rotates freely. For Bowden extruders, inspect the PTFE tube for wear or misalignment.

- Adjust Temperature: Increase the nozzle temperature by 5–10°C if the filament isn’t melting fully. For PLA, try 205–215°C; for ABS, 230–245°C. Print a small test cube to verify flow.

- Inspect Extruder Components: Check the extruder gear for wear or debris buildup. Replace damaged gears or PTFE tubes. Ensure the extruder tension is set correctly—tight enough to grip the filament but not so tight it deforms it.

Test

Print a single-layer square (50 mm x 50 mm) to check for consistent extrusion. If the filament doesn’t flow, repeat the cleaning process or inspect the extruder assembly.

Issue 2: Under-Extrusion

Symptoms

Prints have gaps, weak layers, or missing sections. The filament extrudes inconsistently, producing thin or incomplete lines.

Causes

- Incorrect Flow Rate: The extrusion multiplier may be set too low.

- Partial Nozzle Clog: Small debris can restrict filament flow.

- Filament Diameter Inconsistencies: Variations in filament diameter can cause uneven extrusion.

- Low Print Speed or Temperature: Settings may not match the filament’s requirements.

Solutions

- Calibrate Flow Rate: In your slicer, set the extrusion multiplier to 100% and print a thin-walled test model (e.g., a 0.8 mm thick cylinder). Measure the wall thickness with a caliper; if it’s less than 0.8 mm, increase the flow rate by 2–5% increments until the wall measures correctly.

- Clean the Nozzle: Follow the nozzle cleaning steps from the filament jam section to remove partial clogs.

- Measure Filament Diameter: Use a caliper to measure your filament’s diameter at multiple points. Most printers expect 1.75 mm or 2.85 mm filament. If the diameter varies significantly (±0.1 mm), adjust the slicer’s filament diameter setting or switch to a higher-quality filament.

- Adjust Print Settings: Increase the nozzle temperature by 5°C or reduce print speed to 30–40 mm/s for better melting and flow. For detailed prototypes, use a layer height of 0.1–0.2 mm to improve consistency.

Test

Print a hollow cube with 0.4 mm walls. Measure the walls and check for gaps or weak spots. Adjust settings until the walls are uniform and strong.

Issue 3: Over-Extrusion

Symptoms

Prints have blobs, rough surfaces, or excess material buildup. Layers may appear overly thick or fused together.

Causes

- High Flow Rate: Too much filament is being extruded.

- Incorrect Filament Diameter: The slicer may assume a smaller diameter than the actual filament.

- High Temperature: Excessive heat can cause filament to ooze or spread excessively.

- Improper Retraction: Lack of retraction can lead to excess filament during travel moves.

Solutions

- Calibrate Flow Rate: Print a thin-walled test model and measure the wall thickness. If it’s thicker than expected (e.g., >0.8 mm for a 0.8 mm wall), reduce the flow rate by 2–5% increments until accurate.

- Verify Filament Diameter: Measure the filament with a caliper. If it’s larger than the slicer’s setting (e.g., 1.8 mm instead of 1.75 mm), update the slicer or use a more consistent filament.

- Lower Temperature: Reduce the nozzle temperature by 5–10°C to minimize oozing. For PLA, try 195–205°C; for ABS, 220–235°C. Print a test model to confirm smooth surfaces.

- Tune Retraction: Increase retraction distance (e.g., 0.5–2 mm for direct-drive, 2–4 mm for Bowden) and speed (e.g., 30–40 mm/s). Enable “wipe” or “coasting” in the slicer to reduce excess filament during travel.

Test

Print a model with fine details, like a small gear or textured surface. Check for blobbing or loss of detail. Adjust settings until the print is clean and precise.

General Maintenance Tips

- Regular Nozzle Cleaning: Clean the nozzle every 50–100 print hours to prevent buildup. Use a cold pull or cleaning filament after switching filament types.

- Check Extruder Tension: Ensure the extruder grips the filament firmly without crushing it. Adjust the tension screw if the filament slips or deforms.

- Store Filament Properly: Keep filament in a sealed container with desiccants to prevent moisture absorption, which can cause inconsistent flow or bubbles.

- Lubricate the Filament Path: For Bowden extruders, lightly lubricate the PTFE tube with silicone oil to reduce friction, but avoid over-application to prevent contamination.

- Level the Bed: An uneven bed can mimic flow issues by causing poor adhesion or inconsistent layer heights. Level the bed before each major print.

Testing and Iteration

To troubleshoot effectively, print small test models that highlight specific issues. A 20 mm cube with 0.4 mm walls is ideal for checking flow consistency, while a model with bridges or overhangs can reveal retraction problems. Log your settings (temperature, flow rate, speed, retraction) and results for each test to identify patterns. For example, if under-extrusion persists after cleaning, focus on flow rate or filament quality. Iterate until the print quality meets your prototyping needs.

Practical Tips for Success

- Start with PLA: PLA is easier to troubleshoot than ABS or PETG due to its lower printing temperature and minimal fumes.

- Use High-Quality Filament: Consistent filament diameter and quality reduce flow issues. Measure new spools to confirm specifications.

- Monitor First Layers: Watch the first layer of each print for signs of under- or over-extrusion, as early issues often persist throughout the print.

- Update Firmware: Ensure your printer’s firmware is up-to-date to avoid software-related flow problems.

- Keep a Maintenance Schedule: Clean and inspect your printer monthly to prevent recurring issues.

Benefits for Prototyping

Resolving filament flow issues ensures precise, reliable prints for small-scale prototypes, such as functional parts or intricate designs. Consistent extrusion prevents weak or failed prints, saving time and material. For example, a well-tuned printer can produce a complex prototype with tight tolerances (e.g., ±0.1 mm) in a single print, reducing post-processing.

Conclusion

Troubleshooting filament flow issues requires a systematic approach to identify and resolve problems like jams, under-extrusion, and over-extrusion. By cleaning the nozzle, calibrating settings, and maintaining your 3D printer, you can achieve consistent filament flow for high-quality prints. Test with small models, log results, and iterate to fine-tune your setup. With these techniques, your single-extruder 3D printer will deliver reliable, professional-grade results for all your prototyping projects.